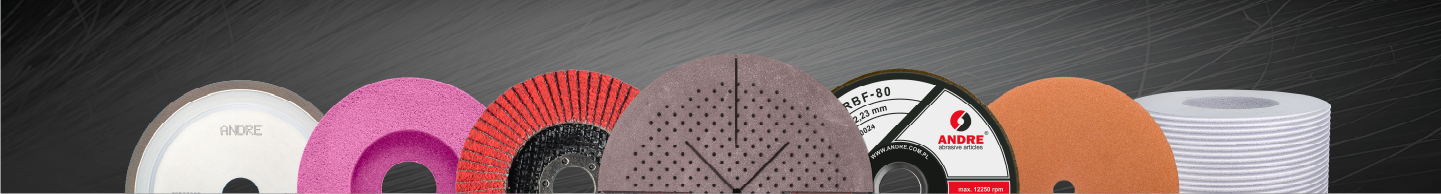

IMPLEMENTATION OF NEW PRODUCTS AND TECHNOLOGIES

ANDRE not only generates new solutions, but also successfully transfers them from the office to the production halls.

From the office to production hall

Efficient implementation of new solutions

The direction of constant search for new, often innovative solutions that ANDRE has chosen seems to be the only right one.

The company’s success in the implementation of new technologies or the production of new products is a consequence of proper analysis and, based on them, further production activities. As it turns out, openness to new solutions and empirical experience in implementations brings rapid development and material results.

Technology first

ANDRE's strengths in terms of new implementations

There are several important advantages of ANDRE, which are behind the company's success in terms of new implementations. First of all, it is know-how in terms of technology. Many years of experience of the company is a knowledge base on how to create a new product with the use of new technology.

Starting innovative production lines is also ANDRE's acquired skill. The company has repeatedly expanded its machinery park, both thanks to subsidies and investing its own resources, what allowed to achieve results significantly exceeding the assumed ones.

Major awards

This is how it has been since the beginning of the company

ANDRE is today one of the leaders in the abrasive industry, awarded many times, respected and trusted by partners.

One of the most important awards is the one given as part of the "Wielkopolska Jakość" competition (Wielkopolska Quality Award).

The company has been awarded several times for its achievements in modern technological solutions in the production of abrasive tools.

The company was awarded the title of Wielkopolska Pillar of Business in the "Product Quality" category in 2003 and 2005.

In 2004, ANDRE was awarded the Gold Medal of the Poznań International Fair for its innovative thin cutting-off wheels Type 41.

In the same year, METAL+INOX thin cutting-off wheels were awarded the European Medal, by the Office of the Committee for European Integration and the BCC (Business Center Club).

ANDRE was awarded the prestigious title of Regional Leader in Innovation and Development for effective implementation of an innovative process of manufacturing and testing the strength of grinding wheels of types 41, 42 and 27. The project was also awarded in the National Leaders in Innovation and Development competition.

RESEARCH DEPARTMENT, LABORATORY AND COOPERATION WITH SCIENTIFIC CENTERS

ANDRE has its own R&D department. This gives a genuine opportunity to improve the technological process, which allows for the permanent development of the company and allows to compete in terms of new solutions and product quality.

In-house R & D department

Research brings new opportunities and benefits

The direction for new solutions plus our own modern laboratory is a recipe for success. It is also the freedom and independence of creative work on ANDRE's own ideas.

The research works carried out at ANDRE, also the exchange of scientific knowledge is simply used to develop products with unique technical parameters, better than those offered by the competition

ANDRE Lab

Quality born inside the company

With the help of the laboratory, ANDRE refines the bonds used in production and searches for new, more innovative ones. An example is the recently developed glass-crystal bond. The company is also conducting research to improve the performance of grinding wheels. For instance a new resin mixture has been introduced recently in the popular Type 41, 1-mm-thick cuting-off wheels.

One of the results of the search for own innovations is the technology of manufacturing abrasive tools with pore agent, both in the case of grinding wheels with small induced porosity and large-pore vitrified wheels.

Exchange of scientific information

Cooperation with scientific centers brings real results

ANDRE has an ongoing, effective exchange of scientific information with various entities on new developments. For many years, various scientific projects were developed together with Koszalin University of Technology, Poznan University of Technology, Rzeszow University of Technology, Lodz University of Technology, Bydgoszcz University of Technology and scientific and research institutions such as Institute of Advanced Manufacturing Technologies in Krakow.

DIRECTION: INNOVATIVE SOLUTIONS

Efficient operation in the modern market and the strong position of ANDRE ABRASIVE ARTICLES results from continuous improvement and meeting the constantly growing customer requirements. The company, following its own development policy, focuses on innovation and invests in new technologies.

Development ….that matters

New technologies and products

ANDRE is a dynamically developing company that has been investing intensively in the broadly understood innovation since its inception. It develops new production technologies, develops new, innovative products and improves existing products. ANDRE also constantly invests in the production assets owned.

Innovation from the beginning

Ideas, patents, work at the grass roots

Zoom on innovation of ANDRE did not come out of nowhere. Robert Andre is a chemist by profession, and since the beginning he has paid special attention to the technological side of the products offered.

Customers know that ANDRE products are subject to continuous development. This is the result of a long-term strategy to expand the company's technological and production capabilities. We are talking about continuous investments in modern machines that allow the production of products in accordance with the latest standards.

Grants for innovation

EU-supported projects

The activity of ANDRE in implementing innovative projects with the support of European Union funds deserves special attention.

EU grants for innovation in 2014-2020

"Implementation of innovative abrasive tools using microaggregates and based on synthetic resin compositions" (Intelligent Development - Polish Agency for Enterprise Development - POIR 3.2.1 - 2015-2017)

"Innovative hybrid abrasive tools for machining light metal alloys" (INNOTECH program - National Center for Research and Development 2013-2016)

EU grants for innovation in 2007-2013

"Implementation of an innovative process for manufacturing and testing the strength of grinding wheels type 41, 42, 27" (Innovative Economy POIG 1.4-4.1 2009-2013)

"New technology for manufacturing grinding wheels with vitrified bond and increased technology" (Innovative Economy POIG 4.3 2011-2012)

"Technology for manufacturing grinding wheels with resin bond with reduced amount of harmful substances emitted to the environment" (Innovative Economy POIG 1.4-4.1 2008-2011)

EU grants for innovation in 2004-2006

"Innovative improvement of the production process of abrasive tools" (SOP WKP 2004-2006) Pre-accession EU grants "Purchase of a modern Maternini press with a pressure of 1250T" (PHARE 2001 Investment Subsidies Fund)

INNOVATIVE TECHNOLOGY – it is the mark on ANDRE projects, which focus on modern solutions.