ANDRE - know-how and experience

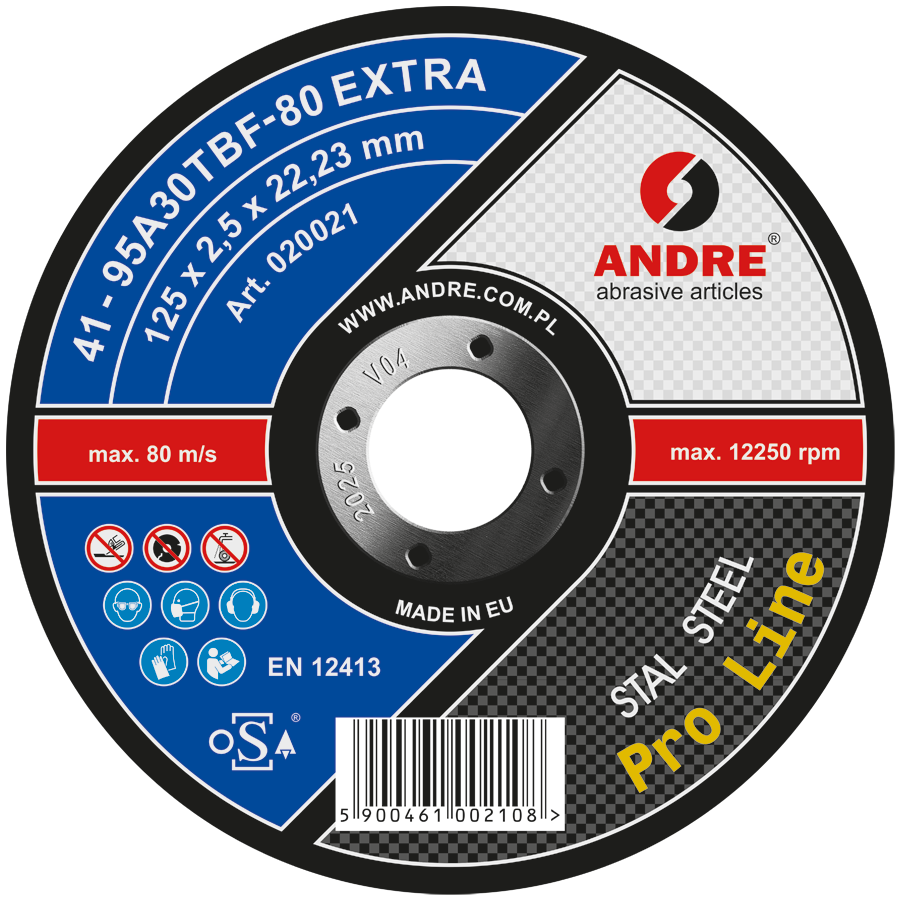

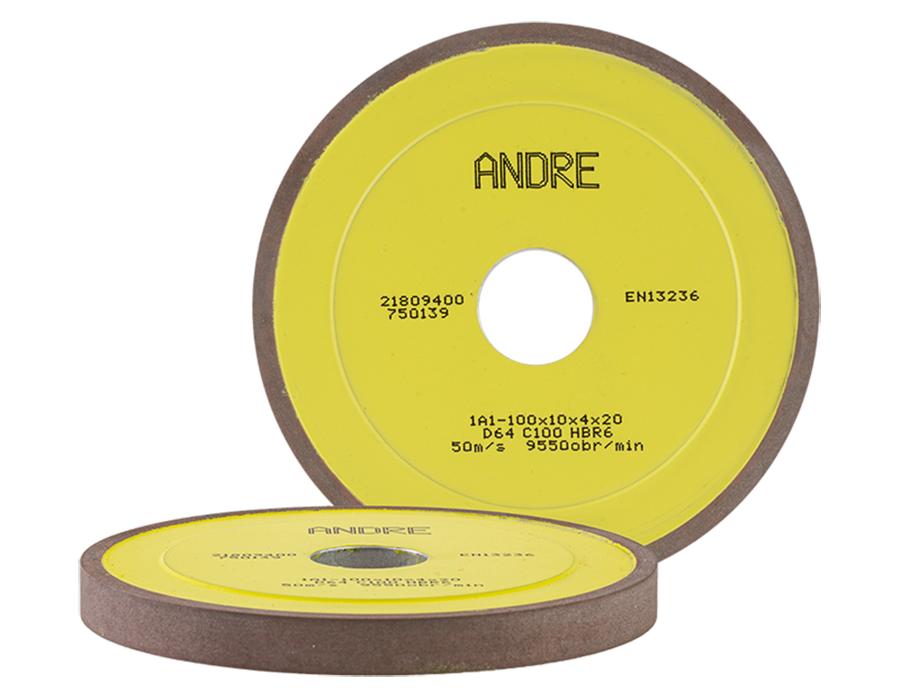

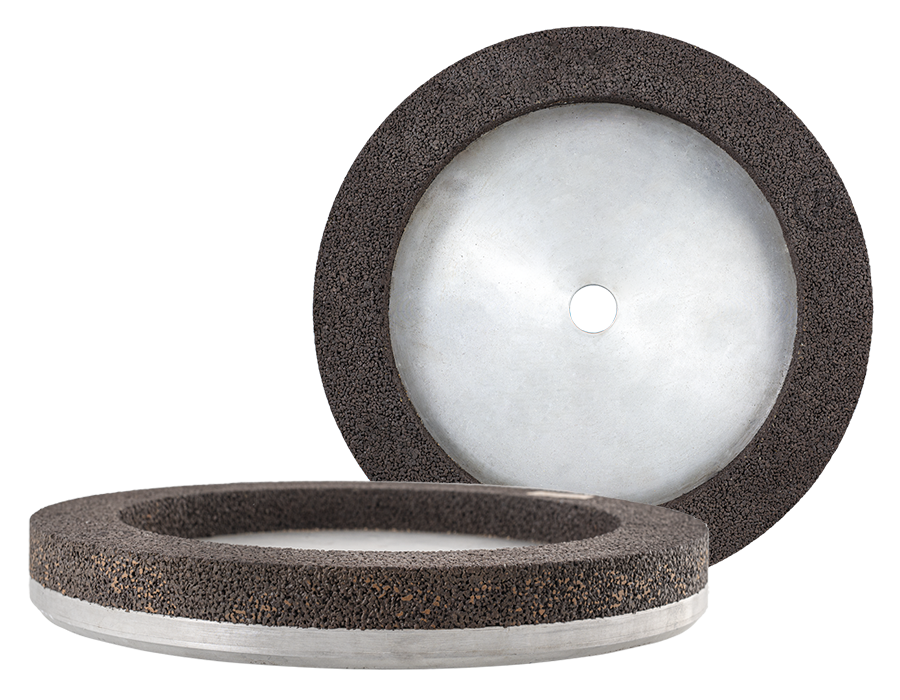

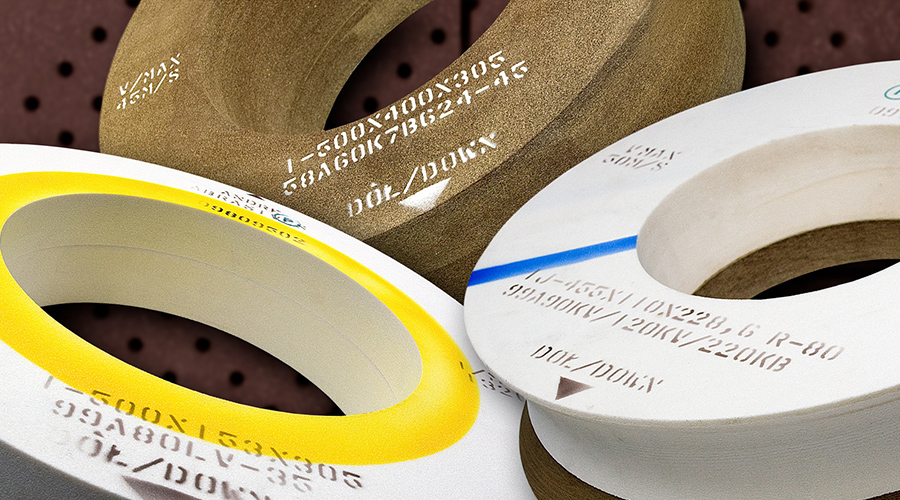

Manufacturer of professional abrasive tools

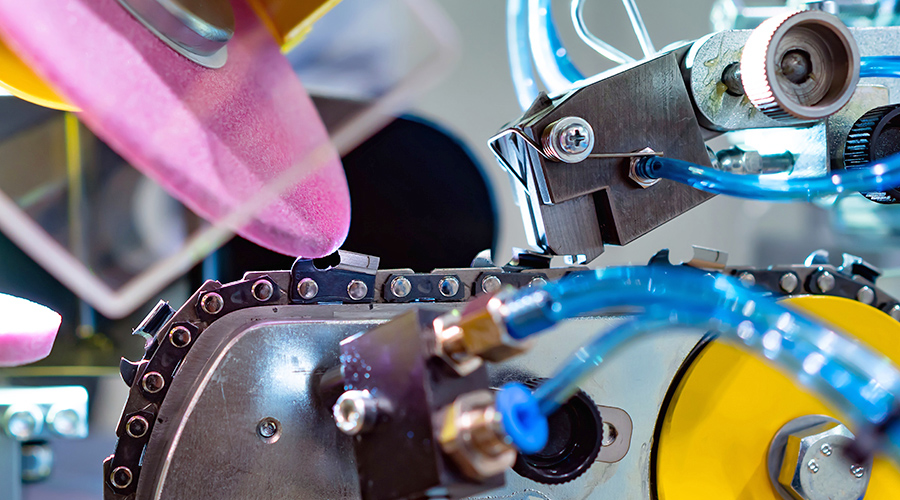

ANDRE is a Polish family-owned company that designs, manufactures and supplies a wide range of resin and ceramic bonded abrasive tools for roughing and precision machining of many types of materials. These are both typical abrasive tools and customized products.

See more