Band saw blade sharpening

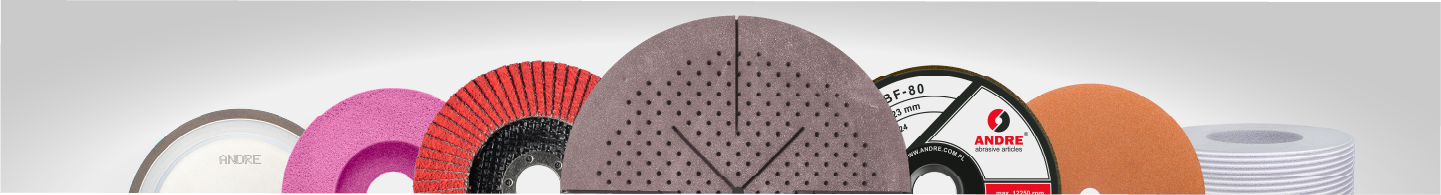

It's a grinding operation to properly sharpen the saw to give it the required properties and long life. This action keeps the cutting surface smooth and generates a small amount of heat during the use of the saw. ANDRE offers a proven range of grinding wheels for sharpening saws, both when it comes to grinding the tooth rake face and their side surface, as well as smoothing welds.

GRINDING OF TOOTH RAKE FACE

| TYPE 1 | TYPE 1C

1 - D x T x H

1C - D x T x H

|

Examples of implemented abrasive tools in industry [*] |

||||

|

Type |

Dimensions [mm] |

Characteristics |

Version |

Speed [m/s] |

|

1 |

127x6x12,7 |

99A60RB89 |

FORMULA 2 |

50 |

|

1 |

150x6x32 |

99A660SB88 |

FORMULA 3 |

50 |

|

1C |

150x8x20 |

95A60N/O8B643 |

- |

50 |

[*] Ask the Sales Department about the full offer and available characteristics.

| PROFILE CBN GRINDING WHEEL

CBN profile - D; H; profile

|

Examples of implemented abrasive tools in industry [*] |

||

|

Type |

Dimensions [mm] |

Profile |

|

CBN PROFILE |

127x22,23E9,5;R15,24;H12,7 |

10/30 (summer profile) |

|

CBN PROFILE |

203,2x22,23 E9,5; H32 |

9/29 (winter profile) |

[*] Ask the Sales Department about the full offer and available characteristics.

GRINDING THE SIDE SURFACE OF THE TOOTH

| TYPE 6A9

6A9 - D x T x X x U x H

|

Examples of implemented abrasive tools in industry [*] |

||

|

Type |

Dimensions [mm] |

Characteristics |

|

6A9 |

100x30x3x10x20 |

B151V180LBL2 |

[*] Ask the Sales Department about the full offer and available characteristics.

GRINDING OF SAW WELDS

The operation is performed to align the weld. ANDRE offers a proven range of grinding wheels for this operation. Only properly selected grinding wheels will ensure quick and burn-free material removal.

| TYPE 6

6 - D x T x H - W...E...

|

Examples of implemented abrasive tools in industry [*] |

|||

|

Type |

Dimensions [mm] |

Characteristics |

Speed [m/s] |

|

6 |

100x50x20-W8E12 |

99A70M7VE02B |

35 |

|

6 |

100x50x20-W8E12 |

99A70M7VTE10 |

35 |

|

6 |

150x51x32-W20E20 |

95A60N/O7VTE10 |

30 |

[*] Ask the Sales Department about the full offer and available characteristics.

Since the beginning of its activity, ANDRE company has been focusing on high quality of its products. At ANDRE, every effort is made to ensure that products meet customers' individual needs and satisfy their highest expectations even in the most difficult grinding operations.

Abrasive tools by ANDRE ABRASIVE ARTICLES are safe.

ANDRE gradually improves its technological process to offer abrasive tools with increasingly better usability and a high safety factor in accordance with the applicable standards. Membership in organizations of leading abrasive tool manufacturers and regular certification fully confirm that.