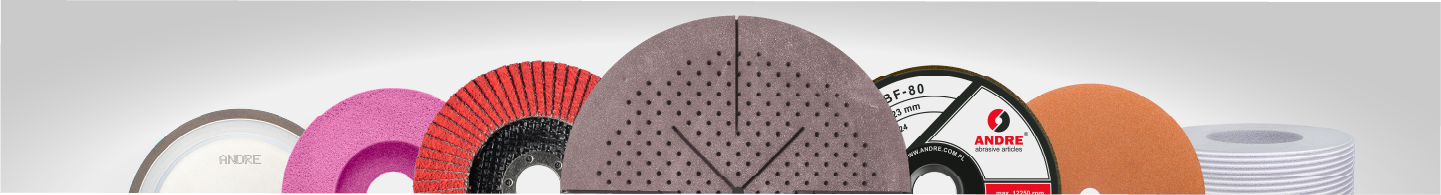

FLAP DISCS

POPULAR FOR MANY APPLICATIONS

ANDRE ABRASIVE ARTICLES flap discs are a group of products that can be used for both rough grinding and finishing. These are some of the best deburring and finishing abrasive tools dedicated for machining all types of metals, especially stainless steel. Used for cleaning steel, aluminum, wood, plastic surfaces, deburring and refracting edges, removing paint and rust, also grinding welds after welding.

Used on hand-held angle grinders.

ANDRE flap wheels are manufactured based on a specially developed composition of abrasive grains with a selected backings.

Depending on the type of abrasive grit, different applications are achieved. Brown aluminium oxide is a first choice for grinding ordinary steels. Zirconia grain is dedicated to high pressure grinding, recommended, both for deburring and finishing of ferrous metals and stainless steels. Ceramic grain is designed for special applications, reducing "loading" of the grinding wheel and "burning" of the workpiece. Just like in case of abrasive grain type, the background itself determines different applications. Cotton works well for grinding planes, steel, small welds, and fine grinding. The most versatile is polyesterized cotton used most often. A good substrate for edge grinding and large welds is heavy polyester.

FLAP DISC - D x H

Examples of labeling:

FLAP DISC -125x22,23 ZRA60 PRO LINE VERSION I

FLAP DISC -125x22,23 ZRA60 PRO LINE VERSION I

Download

A line of professional solutions that meets the condition of a good efficient product at a good price. Dedicated definitely for professional applications.

PRO LINE VERSION I

Use for grinding steel, stainless steel, non-ferrous metals and plastics. Use for surface grinding and small welds. Avoid use for edge grinding and large welds. High power. Average tool life.

|

PRO LINE VERSION I |

||||||

|

Characteristics |

D [mm] |

H [mm] |

RPM |

|||

|

ZrA40 |

125 |

22,23 |

12250 |

|||

|

ZrA60 |

125 |

22,23 |

12250 |

|||

|

ZrA80 |

125 |

22,23 |

12250 |

|||

|

ZrA120 |

125 |

22,23 |

12250 |

|||

*) Other parameters available according to individual arrangements.

PRO LINE VERSION II

Use for grinding steel, stainless steel, non-ferrous metals and plastics. Use for surface grinding and small welds. Avoid use for edge grinding and large welds. Very high power. Average tool life.

|

PRO LINE VERSION II |

||||||

|

Characteristics |

D [mm] |

H [mm] |

RPM |

|||

|

ZrA40 |

115 |

22,23 |

13300 |

|||

|

ZrA60 |

115 |

22,23 |

13300 |

|||

|

ZrA80 |

115 |

22,23 |

13300 |

|||

|

ZrA40 |

125 |

22,23 |

12250 |

|||

|

ZrA60 |

125 |

22,23 |

12250 |

|||

|

ZrA80 |

125 |

22,23 |

12250 |

|||

|

ZrA40 |

180 |

22,23 |

8500 |

|||

|

ZrA60 |

180 |

22,23 |

8500 |

|||

|

ZrA80 |

180 |

22,23 |

8500 |

|||

*) Other parameters available according to individual arrangements.

PRO LINE VERSION III

Universal application for steel, stainless steel, non-ferrous metals and plastics. Use for grinding surfaces, welds and edges. Long tool life and average power.

|

PRO LINE VERSION III |

||||||

|

Characteristics |

D [mm] |

H [mm] |

RPM |

|||

|

ZrA40 |

125 |

22,23 |

12250 |

|||

|

ZrA60 |

125 |

22,23 |

12250 |

|||

|

ZrA80 |

125 |

22,23 |

12250 |

|||

|

ZrA120 |

125 |

22,23 |

12250 |

|||

*) Other parameters available according to individual arrangements.

PRO LINE VERSION IV

Use for steel, stainless steel, non-ferrous metals and plastics. Use for grinding edges and welds at high pressure. More aggressive in performance than Pro Line Version III. Very long tool life.

|

PRO LINE VERSION IV |

||||||

|

Characteristics |

D [mm] |

H [mm] |

RPM |

|||

|

ZrA40 |

125 |

22,23 |

12250 |

|||

|

ZrA60 |

125 |

22,23 |

12250 |

|||

|

ZrA80 |

125 |

22,23 |

12250 |

|||

|

ZrA120 |

125 |

22,23 |

12250 |

|||

*) Other parameters available according to individual arrangements.

A line of economic solutions that meets the condition of a good price for the customer, while providing good performance and a high safety factor.

ECO LINE VERSION I

Universal application mainly for steel (do not use for grinding stainless steel) also for non-ferrous metals. Use for surface grinding and small welds. Avoid use for edge grinding and large welds

Average tool life and power.

|

ECO LINE VERSION I |

||||||

|

Characteristics |

D [mm] |

H [mm] |

RPM |

|||

|

A40 |

125 |

22,23 |

12250 |

|||

|

A60 |

125 |

22,23 |

12250 |

|||

|

A80 |

125 |

22,23 |

12250 |

|||

*) Other parameters available according to individual arrangements.

ECO LINE VERSION II

Use for grinding steel (do not use for grinding stainless steel), also for grinding aluminum and non-ferrous metals. Use for surface grinding and small welds. Avoid use for edge grinding and large welds. High tool life and high power.

|

ECO LINE VERSION II |

||||||

|

Characteristics |

D [mm] |

H [mm] |

RPM |

|||

|

A40 |

125 |

22,23 |

12250 |

|||

|

A60 |

125 |

22,23 |

12250 |

|||

|

A80 |

125 |

22,23 |

12250 |

|||

*) Other parameters available according to individual arrangements.

ECO LINE VERSION III

Use for grinding steel (do not use for grinding stainless steel), also for non-ferrous metals. Use for surface grinding. Avoid use for edge grinding and welds. Average tool life and power.

|

ECO LINE VERSION III |

||||||

|

Characteristics |

D [mm] |

H [mm] |

RPM |

|||

|

A40 |

125 |

22,23 |

12250 |

|||

|

A60 |

125 |

22,23 |

12250 |

|||

|

A80 |

125 |

22,23 |

12250 |

|||

*) Other parameters available according to individual arrangements.

ECO LINE VERSION IV

Use for grinding steel (do not use for grinding stainless steel), also for grinding aluminum and non-ferrous metals. Use for surface grinding and small welds. Avoid use for edge grinding and large welds. Average tool life and high power.

|

ECO LINE VERSION IV |

||||||

|

Characteristics |

D [mm] |

H [mm] |

RPM |

|||

|

A40 |

125 |

22,23 |

12250 |

|||

|

A60 |

125 |

22,23 |

12250 |

|||

|

A80 |

125 |

22,23 |

12250 |

|||

*) Other parameters available according to individual arrangements.

A line of solutions for specific applications, meeting the condition of an extremely efficient product.

MASTER LINE VERSION I

Universal application for steel, stainless steel and non-ferrous metals. High aggressiveness and very long tool life. Cool grinding.

|

MASTER LINE VERSION I |

||||||

|

Characteristics |

D [mm] |

H [mm] |

RPM |

|||

|

Ca40 |

125 |

22,23 |

12250 |

|||

|

Ca60 |

125 |

22,23 |

12250 |

|||

|

Ca80 |

125 |

22,23 |

12250 |

|||

|

Ca120 |

125 |

22,23 |

12250 |

|||

*) Other parameters available according to individual arrangements.

MASTER LINE VERSION II

Use for stainless steel. Use for grinding edges, planes and welds at high pressure. High aggressiveness. Very long tool life. Cool grinding.

|

MASTER LINE VERSION II |

||||||

|

Characteristics |

D [mm] |

H [mm] |

RPM |

|||

|

Ca40 |

125 |

22,23 |

12250 |

|||

|

Ca60 |

125 |

22,23 |

12250 |

|||

*) Other parameters available according to individual arrangements.

MASTER LINE VERSION III

Use for stainless steel. Use for grinding edges, planes and welds at high pressure. Very High aggressiveness. Long tool life. Cool grinding More aggressive in performance than Master Line Version II.

|

MASTER LINE VERSION III |

||||||

|

Characteristics |

D [mm] |

H [mm] |

RPM |

|||

|

Ca40 |

125 |

22,23 |

12250 |

|||

|

Ca60 |

125 |

22,23 |

12250 |

|||

|

Ca80 |

125 |

22,23 |

12250 |

|||

|

Ca120 |

125 |

22,23 |

12250 |

|||

*) Other parameters available according to individual arrangements.

MASTER LINE VERSION IV

Use for surface grinding. The special design of the flap disc with two types of alternating flaps with different substrates and grain, combines the advantages of Master Line and Pro Line flap discs.

|

MASTER LINE VERSION IV |

||||||

|

Charakteristics |

D [mm] |

H [mm] |

RPM |

|||

|

Ca40 |

125 |

22,23 |

12250 |

|||

|

Ca60 |

125 |

22,23 |

12250 |

|||

*) Other parameters available according to individual arrangements.

Purpose / application of individual versions of flap disces

|

Application |

FLAP DISCS |

||||||||||||

|

ECO LINE |

PRO LINE |

MASTER LINE |

|||||||||||

|

I |

II |

III |

IV |

I |

II |

III |

IV |

I |

II |

III |

IV |

||

|

Workpiece material |

Steel |

x |

x |

x |

xx |

x |

x |

x |

xx |

x |

x |

x |

xx |

|

Stainless steel |

x |

x |

x |

xx |

x |

x |

xx |

xx |

|||||

|

Non-ferrous metals |

x |

x |

x |

x |

x |

x |

x |

x |

x |

x |

x |

||

|

Plastics |

x |

x |

x |

x |

x |

x |

x |

x |

x |

x |

x |

||

|

Aluminium |

x |

x |

x |

x |

x |

x |

x |

x |

x |

||||

|

Operation |

Surface |

x |

x |

x |

x |

x |

x |

x |

x |

x |

x |

x |

x |

|

Small welds |

x |

x |

x |

x |

x |

x |

x |

x |

x |

||||

|

Edges |

x |

x |

x |

x |

x |

||||||||

|

Large welds |

x |

xx |

xx |

x |

xx |

||||||||

Efficiency of individual versions of flap disces

|

Efficiency |

FLAP DISCS |

||||||||||||

|

ECO LINE |

PRO LINE |

MASTER LINE |

|||||||||||

|

I |

II |

III |

IV |

I |

II |

III |

IV |

I |

II |

III |

IV |

||

|

Aggressivness (Power) |

Average |

x |

x |

x |

|||||||||

|

High |

x |

x |

x |

x |

x |

||||||||

|

Very high |

x |

x |

x |

x |

|||||||||

|

Tool life |

Average |

x |

x |

x |

x |

x |

|||||||

|

High |

x |

x |

x |

x |

|||||||||

|

Very high |

x |

x |

x |

||||||||||

The presented abrasive tools ANDRE ABRASIVE ARTICLES have been manufactured based on knowledge and long-term experience of cooperation with customers.

Since the beginning of its activity, ANDRE company has been focusing on high quality of its products. At ANDRE, every effort is made to ensure that products meet customers' individual needs and satisfy their highest expectations even in the most difficult grinding operations.

Abrasive tools by ANDRE ABRASIVE ARTICLES are safe.

ANDRE gradually improves its technological process to offer abrasive tools with increasingly better usability and a high safety factor in accordance with the applicable standards. Membership in organizations of leading abrasive tool manufacturers and regular certification fully confirm that.