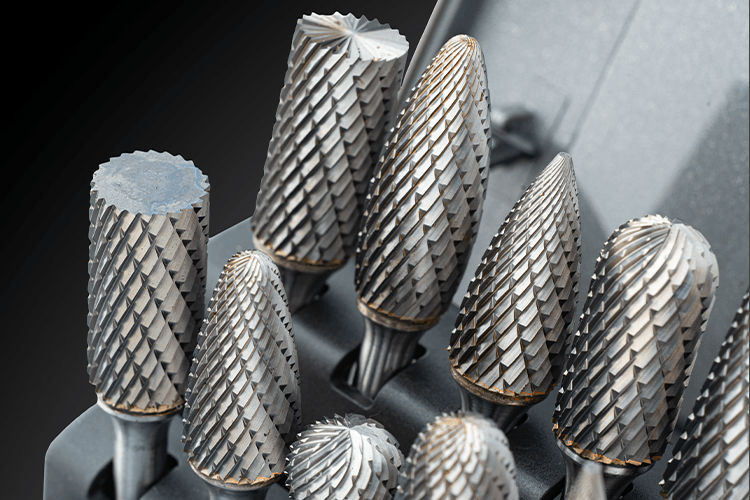

Rotary burrs

ANDRE ABRASIVE ARTICLES rotary burrs are powerful tools designed to perform general material removal operations primarily on welds, using high-speed grinders. Thanks to the appropriately selected shape and geometry of the blade, it is possible to choose the right tools for specific operations, meeting the expectations of even very demanding users.

Tungsten carbide really works...

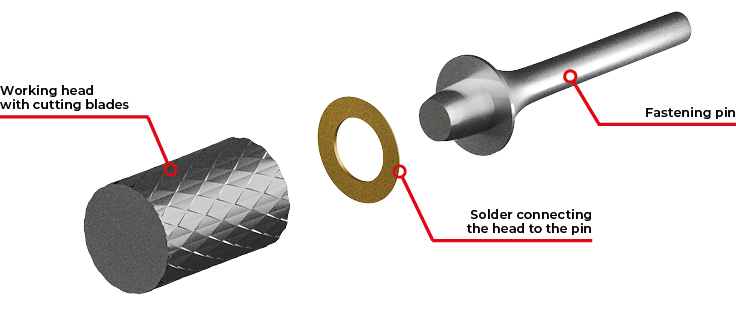

When precision and time of operations are important, tungsten carbide rotary burrs may be a suitable option. It is excellent solution when grinding profiles, during finishing and also for smoothing surface irregularities. Rotary burrs, like mounted points, are built from two parts - the working head and the pin.

ANDRE rotary burrs are characterized by high quality and safety.

Example of rotary burr design

Applications of rotary burrs

Various operations

Machining of various materials including: steel, other metals, wood, plastics

Machining of welds, using high speed grinders

Various industries

Used in many different industries, e.g. aviation, automotive, shipbuilding, foundry and steel construction

Features of rotary burrs

short chip

no clogging

high efficiency

stable operation

long life (when used properly)

unique geometry of cutting blades - made on CNC machines

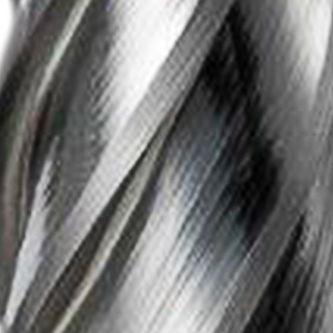

Geometry of the blade

EXTRA

Features: short chip, no clogging, uniform high-efficiency operation. Application: steel, hardened steel, inox, cast iron, copper, titanium, nickel.

EXTRA PLUS

Features: increased productivity and machining speed by 35% compared to EXTRA blade, higher stock removal, reduced heat generation during machining, increased tool life. Application: steel, hardened steel, cast iron.

ALUMINIUM

Features: effective machining of aluminum alloys and plastics, easy chip removal.

Application: aluminum, plastics.

STANDARD

Features: wide range of applications, easy to achieve high surface smoothness without scratching. Application: steel, inox, cast iron, copper, titanium, nickel.

INOX

Features: fast processing of stainless and acid-resistant steels, higher stock removal

Application: inox stainless steel.

ROTARY BURRS

...to meet your needs.

TYPE A

CYLINDRICAL ROTARY BURRS TYPE A

For rough and fine grinding with hand grinders

Get to know the products

TYPE B

CYLINDRICAL END CUT ROTARY BURRS TYPE B

For rough and fine grinding with hand grinders

Get to know the products

TYPE C

CYLINDRICAL ROUND NOSE ROTARY BURRS TYPE C

For rough and fine grinding with hand grinders

Get to know the products

TYPE D

SPHERICAL ROTARY BURRS TYPE D

For rough and fine grinding with hand grinders

Get to know the products

TYPE E

OVAL ROTARY BURRS TYPE E

For rough and fine grinding with hand grinders

Get to know the products

TYPE F

TAPERED POINTED NOSE ROTARY BURRS TYPE F

For rough and fine grinding with hand grinders

Get to know the products

TYPE G

TAPERED POINTED NOSE ROTARY BURRS TYPE G

For rough and fine grinding with hand grinders

Get to know the products

TYPE H

FLAME ROTARY BURRS TYPE H

For rough and fine grinding with hand grinders

Get to know the products

TYPE J

CONICAL ROTARY BURRS TYPE J (60˚ countersink)

For rough and fine grinding with hand grinders

Get to know the products

TYPE K

CONICAL ROTARY BURRS TYPE K (90˚ countersink)

For rough and fine grinding with hand grinders

Get to know the products

TYPE L

CONICAL ROUND NOSE ROTARY BURRS TYPE L

For rough and fine grinding with hand grinders

Get to know the products

TYPE M

CONICAL POINTED NOSE ROTARY BURRS TYPE M

For rough and fine grinding with hand grinders

Get to know the products

TYPE N

INVERTED CONICAL ROTARY BURRS TYPE N

For rough and fine grinding with hand grinders

Get to know the products

Top quality raw materials

Bei ANDRE ABRASIVE ARTICLES wird Hartmetall für die Herstellung von Frässtifte verwendet, hauptsächlich aus Wolframcarbid. Aufgrund seiner hohen Härte wird es unter anderem in Schneidwerkzeugen und auf Glättungsmaschinen eingesetzt. Er stellt eine interessante, temperaturbeständigere Alternative zu Diamant dar.

Abrasive tools by ANDRE ABRASIVE ARTICLES are safe.

ANDRE gradually improves its technological process to offer abrasive tools with increasingly better usability and a high safety factor in accordance with the applicable standards. Membership in organizations of leading abrasive tool manufacturers and regular certification fully confirm that.

FEDERATION OF EUROPEAN PRODUCERS OF ABRASIVES